Structure of MMI Menu of Hanwha SM482L

From: Author: Publish time:2021-06-22 10:22 Clicks:178

The menu structure and the functions of each menu of MMI (Man-Machine Interface), which serves as the application program for the operation of this machine, are briefly explained in this chapter. For detailed information on each menu, please refer to “Chapter 6Board Definition” ~ “Chapter 16 Production Information Management”.

2.1. Man-Machine Interface (MMI)

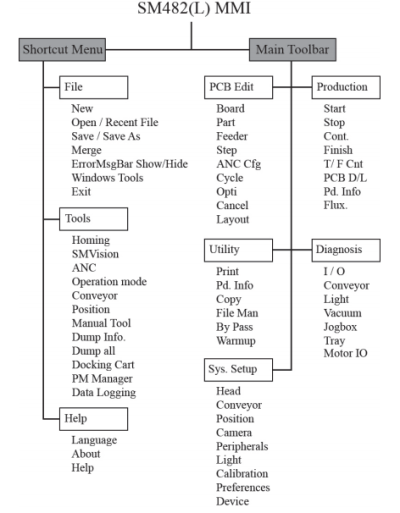

2.1.1. Menu Tree

Figure2.1 Menu Tree of MM

2.1.2. Summary of functions

This section includes information on all the menus that are displayed on the MMI main

window.

2.1.2.1. The submenus of Shortcut Menu

2.1.2.1.1. File Shortcut Menu

- New

Used to create a new PCB file.

- Open

Used to edit an existing PCB file.

- Save

Used to save an opened file.

- Save As

Used to save an opened file under a different name.

- Recent File

Displays a list of files worked on recently.

- Merge

Merges the part library files.

- ErrorMsgBar Show/Hide

ErrorMsgBar Show/Hide.

- Windows Tools

Explorer: Indicates the Windows Explorer.

Calculator: Indicates the calculator.

Paint: Indicates the Paint.

Notepad: Indicates the Notepad.

- Exit

Ends MMI session and goes back to Windows or terminates the operation of the

machine.

2.1.2.1.2. Tools Shortcut Menu

- Homing

Returns the motors for the X, Y, Z, theta (R) and mirror axes to the point of origin.

- SMVision

Changes the operation mode.

- ANC

Registers various information on the ANC (Auto Nozzle Changer).

- Operation mode

Changes the operation mode.

- Conveyor

Executes the conveyor dialog box.

- Position

Used when it is necessary to refer to the current coordinate of each driving axis during

teaching or calibration.

- Manual Tool

Used when it is necessary to refer to the current coordinate of each driving axis during

teaching or calibration.

- Dump Info.

Used to check the message window indicating the information on the parts and feeders

dumped due to placement error.

- Dump all

Used to dump all parts picked up by the head to the dump box.

- Docking Cart

Used to manipulate the movement of the docking cart clamp in the machine to which

the docking cart is applied.

- PM Manager

The PM Manager is a management menu that is used for the maintenance of the

machine in the MMI (Man-Machine Interface), an application program for machine

operation. The items to be inspected as well as check periods can be checked through

the PM Manager, and the machine can be managed more efficiently through the

schedule check function. For more details, refer to the “Appendix. PM Manager’s

Guide” of “Administrator’s Guide”. w Data Logging

Used to find the cause of problems occurring in the machine.

2.1.2.1.3. The submenus of the help menu

- Language

Enables indication of the messages in English while operating the equipment.

- About

Displays the equipment’s application program’s current version and miscellaneous

information.

- Help

Provides the help in HTML format for the application program of this equipment.

2.1.2.2. Main Toolbar

2.1.2.2.1. The submenu tool-bars of the PCB Edit menu tool-bar

- Board

Register various information on the board to be produced..

- Part

Register various information about the components to be placed.

- Feeder

Sets the data related to the Tape, Stick, and Tray Feeder.

- Step

Defines the step for placement operation.

- ANC Cfg

Displays the nozzle information in case the ANC setting of the current PCB file is

different from that of the current system.

- Cycle

Checks the cycle by step.

- Opti

Executes Optimizer..

- Cancel

Closes the dialog box for the Board, Part, Feeder, and Step.

- Layout

Indicates the shape of PCB and placement position of the parts.

Keywords:

SMT pick and place machine, JUKI RS-1R pick and place machine, JUKI RX-7R pick and place machine, JUKI Pick and place Machine, Samsung Pick and Place Machine, Hanwha SM481 Plus Pick and Place Machine, SMT482Plus, SMT 471Plus, SM321, SM421, SM451, SM485, SCM-1, SLM100, SLM120, EXCEN PRO M, DECAN F2, DECAN L2, DECAN S2, DECAN S1, HM520, Yamaha Pick and Place Machine, Panasonic Pick and Place Machine, FUJI Pick and Place Machine, Siemens Pick and Place Machine, Samsung SMT Mounter, Samsung Chip Mounter, Samsung Chip Shooter, Samsung Chip Placement.

ETA is a manufacturer of SMT machines, has more than 25 researches on SMT and DIP technology, It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc.

ETA for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

ETA provide SMT solutions at various stages according to the different needs of customers. ETA is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information: WhatsApp/ Skype / WeChat: +86-13670124230,Email: etasmt@foxmail.com